Kaw Valley AR Dimpling Jig Review

When building an AR15, attaching the gas block to the barrel is often one of the most challenging tasks. The idea of taking a drill to a brand new barrel can be more than a little disconcerting. The Kaw Valley Precision AR-15 Gas Block Dimpling Jig takes the stress out of the process of dimpling a barrel for set screw gas blocks.

Kaw Valley’s AR Dimpling Jig comes as a set that includes the jig itself and two different set screws. The alignment set screw has a sharp point for keeping the jig centered on the barrel’s gas port. The non-marring set screw just helps to hold everything in place while drilling.

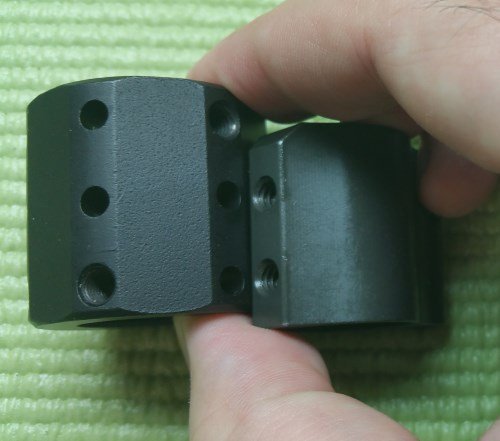

The jig is designed to work with barrels sized for standard 0.750 gas blocks. One of the improvements in the Kaw Valley model over similar products is that it can be used with a variety of different manufacturer’s gas blocks. The problem is that there is no single standard for the set screw spacing. So, this dimpling jig is six-sided, with clearly marked hole setups for 0.400, 0.420, 0.450, 0.460, 0.470, and 0.500 screw spacings.

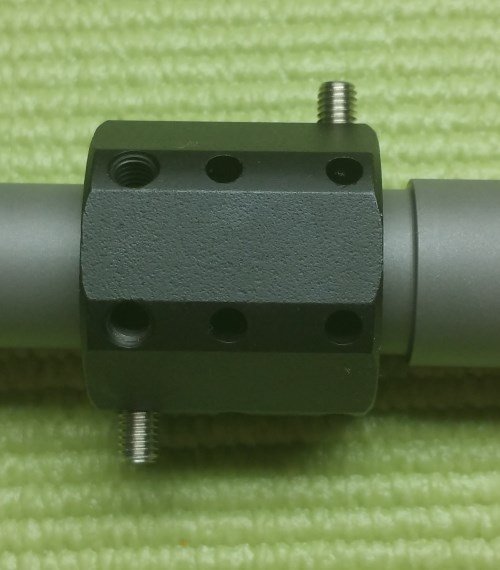

There are a few different ways to find out which spacing the manufacturer used for a gas block. Some vendors supply the information on their websites. If the toolbox is handy, a set of calipers will quickly give you a definitive center to center hole measurement. However, we found that it worked just as well to align the holes on the bottom of the gas block with the ones on the jig and match them up. Our Midwest Industries Micro Gas Block lined up with the 0.460 inch hole spacing, which is a common choice used by at least nine different manufacturers.

After finding the correct hole spacing, set everything up by screwing in the non-marring screw just a few twists on that same side of the jig, next to the drill holes. This is going to be the “bottom side” of the jig and the opposite set of holes is going to be the “top side”. Make sure that the end of the set screw does not stick out into the jig’s central hole. Then, slide the jig onto the barrel, as if it were a gas block. Align the gas port on the barrel so it is centered in the threaded hole on the “top side” of the jig. This will put the non-marring set screw and the correct set of drilling holes on the bottom of the barrel. While holding the jig in place, carefully thread the pointed, alignment set screw into the hole above the gas port and snug it hand-tight with an Allen wrench. Then, tighten the non-marring set screw.

The Kaw Valley AR Dimpling Jig has flats between each side for mounting the barrel and jig in a vise. This allows the vise to tighten on the steel jig rather than the barrel itself, which makes it easy keep everything aligned. It is also much less likely to mar the finish on the barrel.

With a 9/64 drill bit, we were able to quickly make a perfect pair of dimples. Taking your time and using the slowest speed on your drill makes this easy work. These just need to be deep enough to hold the tip of the set screws, which only takes seconds of drilling. The Kaw Valley Precision Jig takes the guesswork out of dimpling like a professional.

If you are looking to build your first AR type rifle, then check out Aero Precision’s 10% off your first order deal: 10% Off Your First Purchase at Aero Precision – Coupon Code: SAVE10NOW